PROJECT OVERVIEW:

•Oakley, Inc. had a need to increase speed-to-market from product design to commercialization.

•Part of the product release process included long development times for unique fixturing.

•In addition, fixtures were known to create manufacturing defects resulting in scrap.

•The purpose of this project was to re-design a base that can be used across all product families, eliminating the need to design unique fixture and reducing manufacturing defects causing scrap material.

•Creating standardized fixturing would reduce first article lead time from 16 to 14 days.

Sunglass Base - Redesign Project.

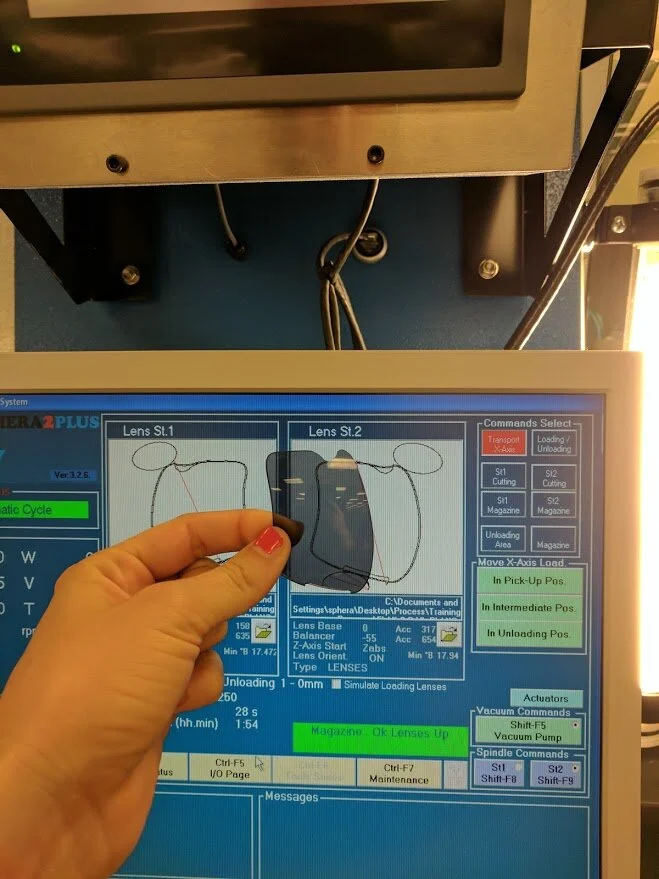

Original Base.

This fixture is machined out of resin and topped with a rubber top using adhesive glue. There were a few problems that needed to be solved with this base. The first is the development time. Each sunglass lens had a unique base meaning that for every new product we created a new base would also need to be created. The second problem with the base is when sunglasses were being cut it would heat up the adhesive and leave glue residue on the sunglass lenses.

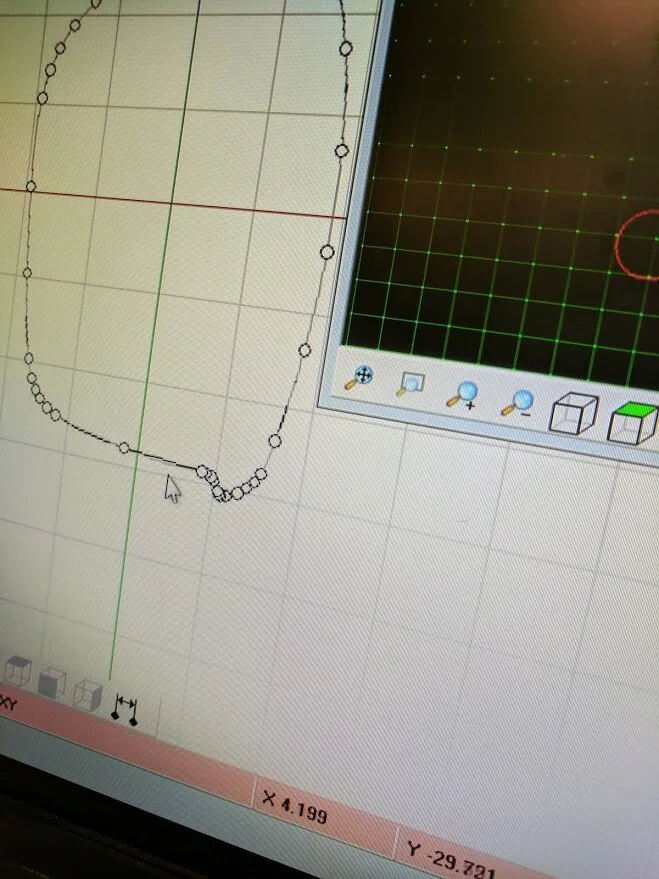

Prototype of New Design.

This new design standardizes the shape of the base. It could be used for all old product as well as future product thus reducing development time and time to market. The other change is the top being urethane material that does not leave defects on the lens.

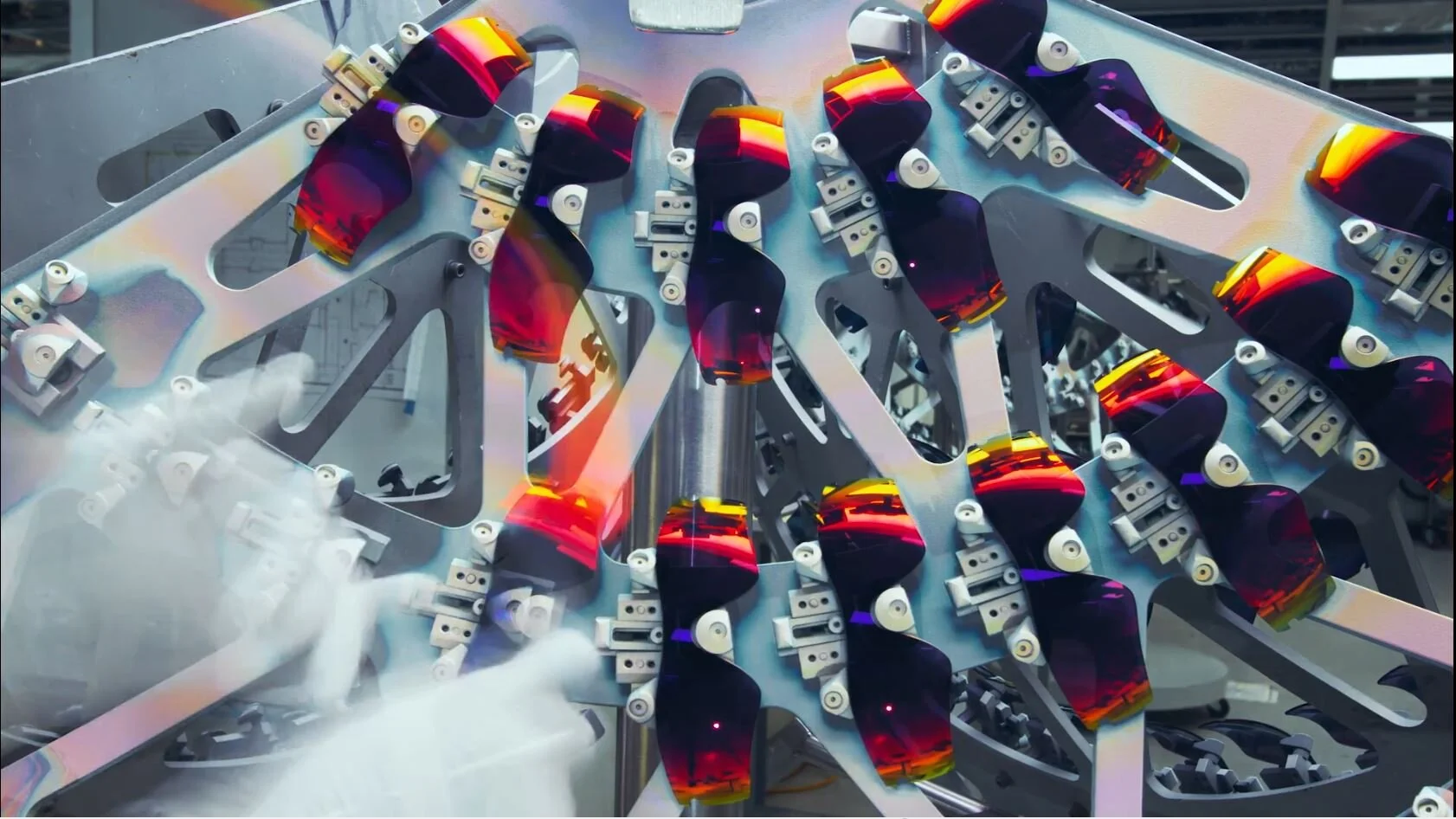

Final Product.

After the shape and material had been determined, I worked with an outside vendor to mold a large quantity of bases out of urethane to reduce variation in height.

PROJECT RESULTS:

•Decreased development lead time 12%

•Savings in scrap reductions $250,000/year

•Labor efficiency savings = $32,000 per year

VIDEO OF BASE